2021-09-26

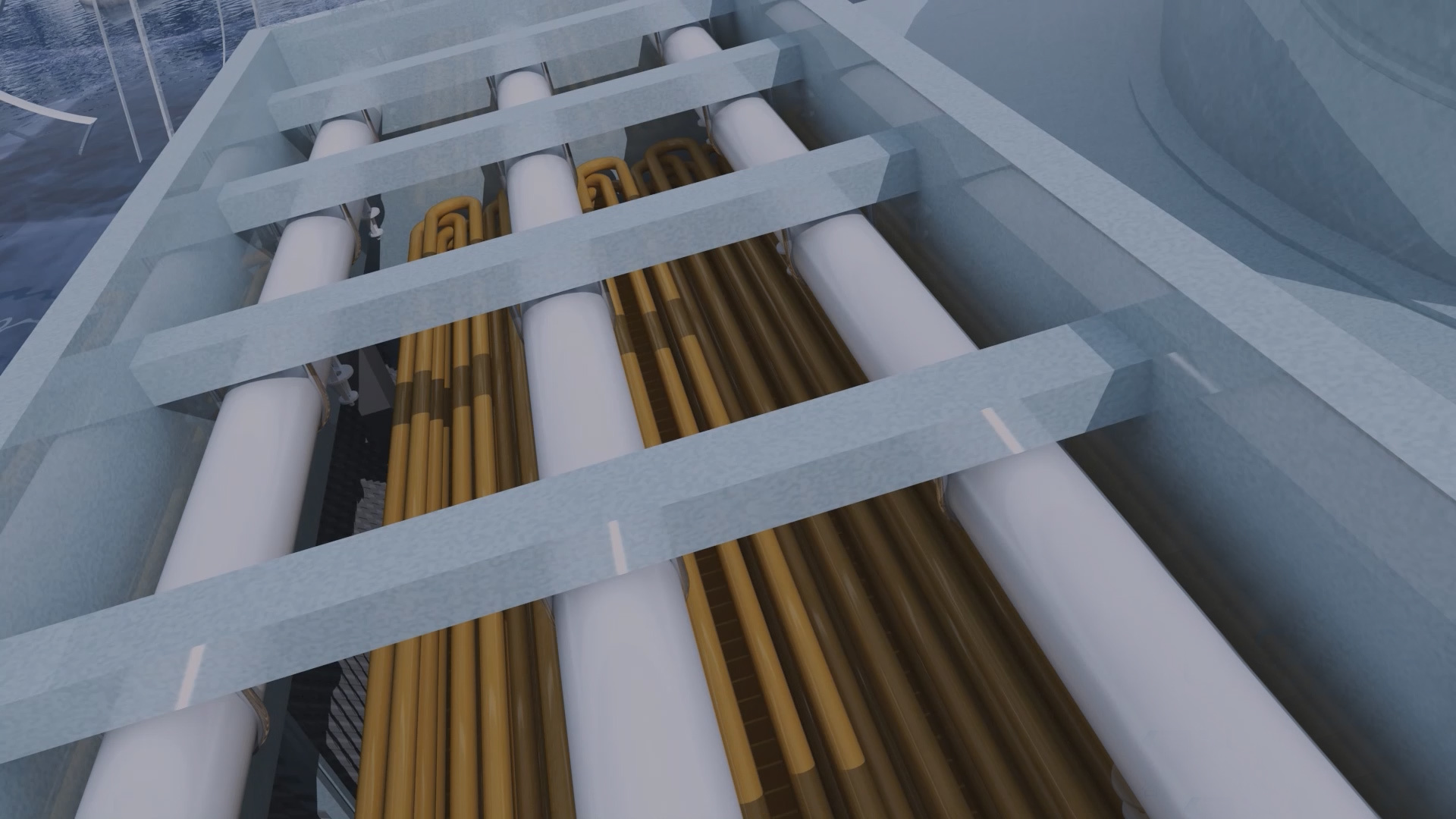

Counterflow closed cooling tower

Vantage

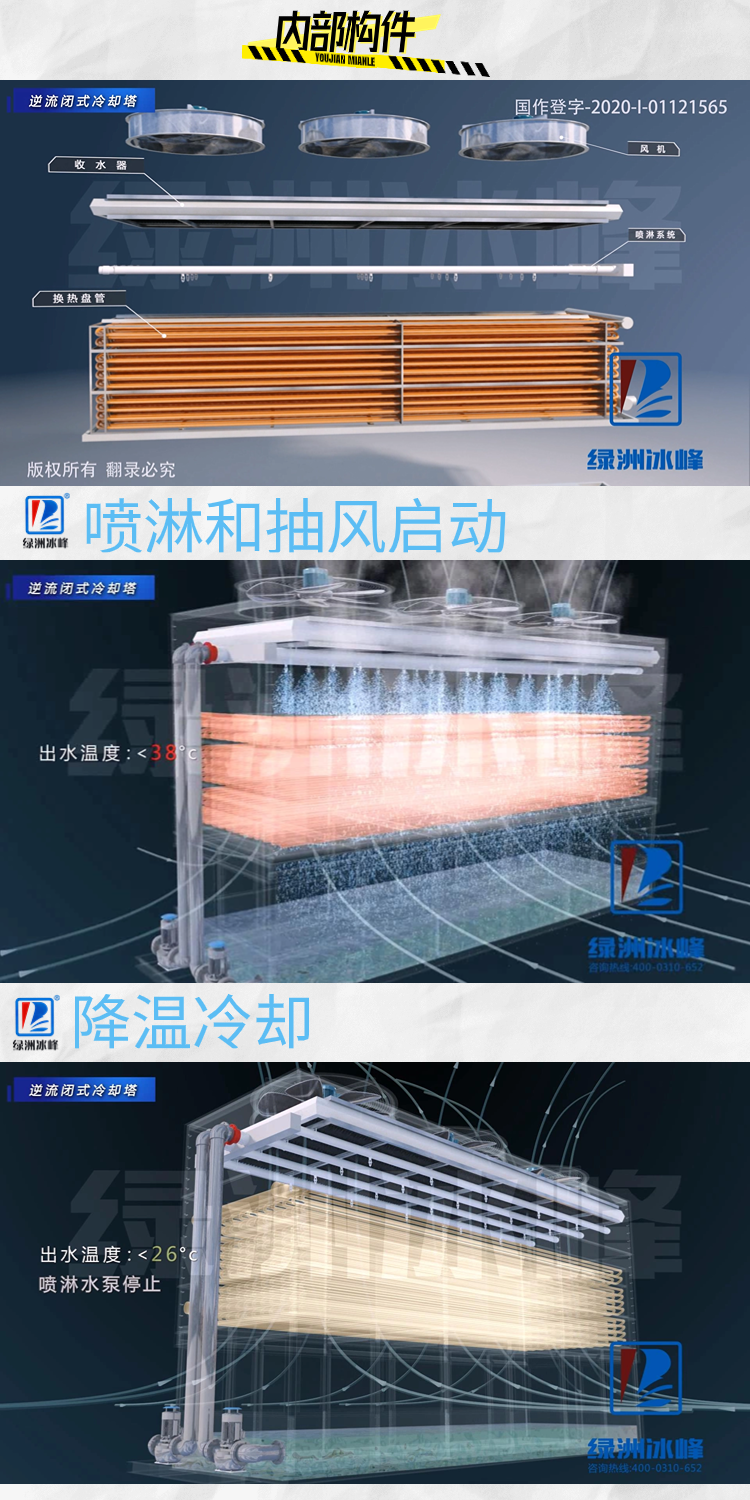

★Air and spray water flow in the reverse direction;

★Low-temperature, low-humidity air is drawn into the tower from the inlet grille, due to the negative pressure caused by the fan;

★High temperature, high humidity air, from the top of the tower fan, outward discharge;

★The cooling medium, heat exchanger coil, after the latent heat of vaporization and tube heat transfer, cooling out;

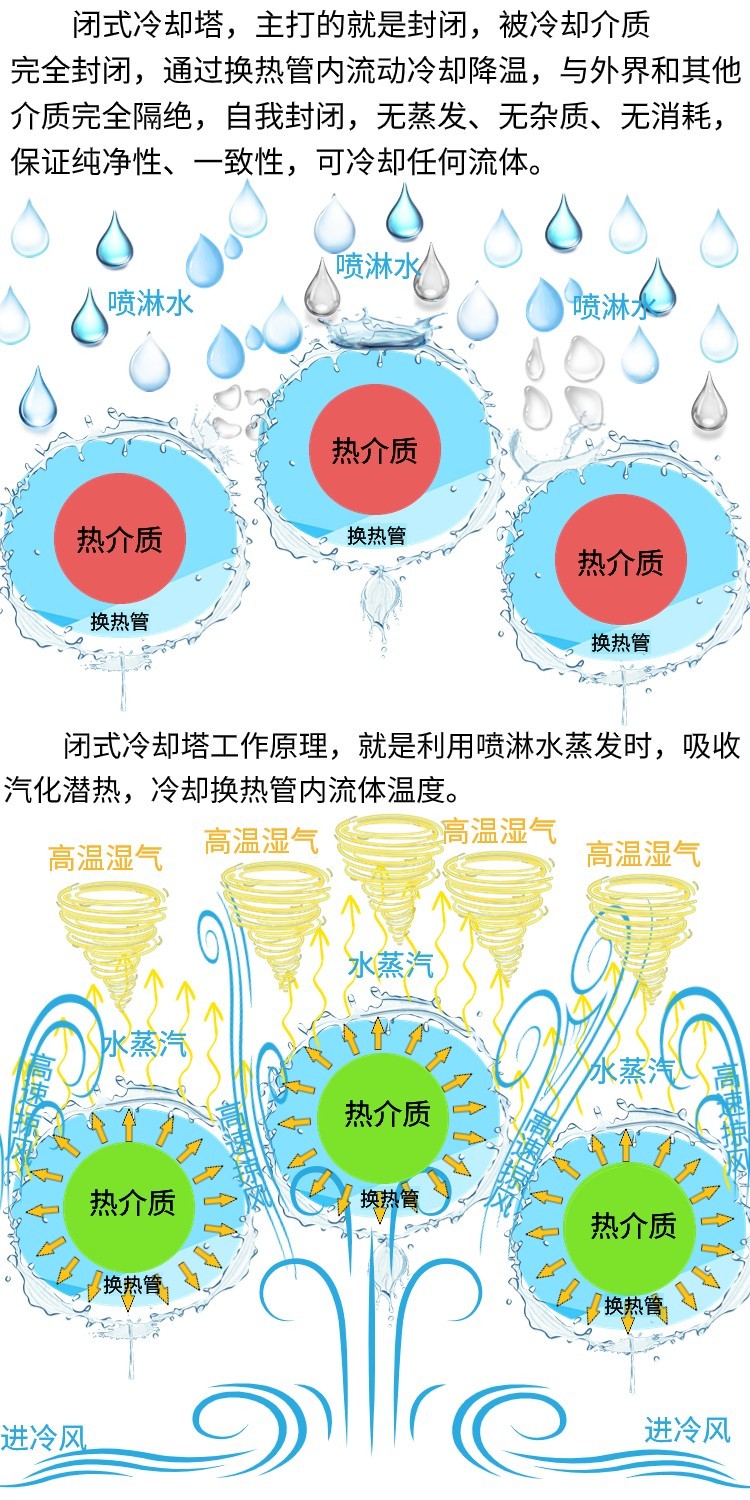

★Spray water, evenly sprayed on the surface of the heat exchanger coil, part of the evaporation, part of the drip back to the spray tank;

★Spray water in the heat exchanger pipe appearance to form a very thin water film;

★ water film absorbs the heat energy of the medium inside the tube, reduce the temperature of the medium inside the tube;

★ water film heated, water vaporization, absorption of latent heat of vaporization;

★ water vapor by the pipe outside the swept dry air away;

★ air and pipe appearance, convective heat exchanger take away some of the heat energy;

★ high temperature and high humidity air, through the fan, discharged outside the tower;

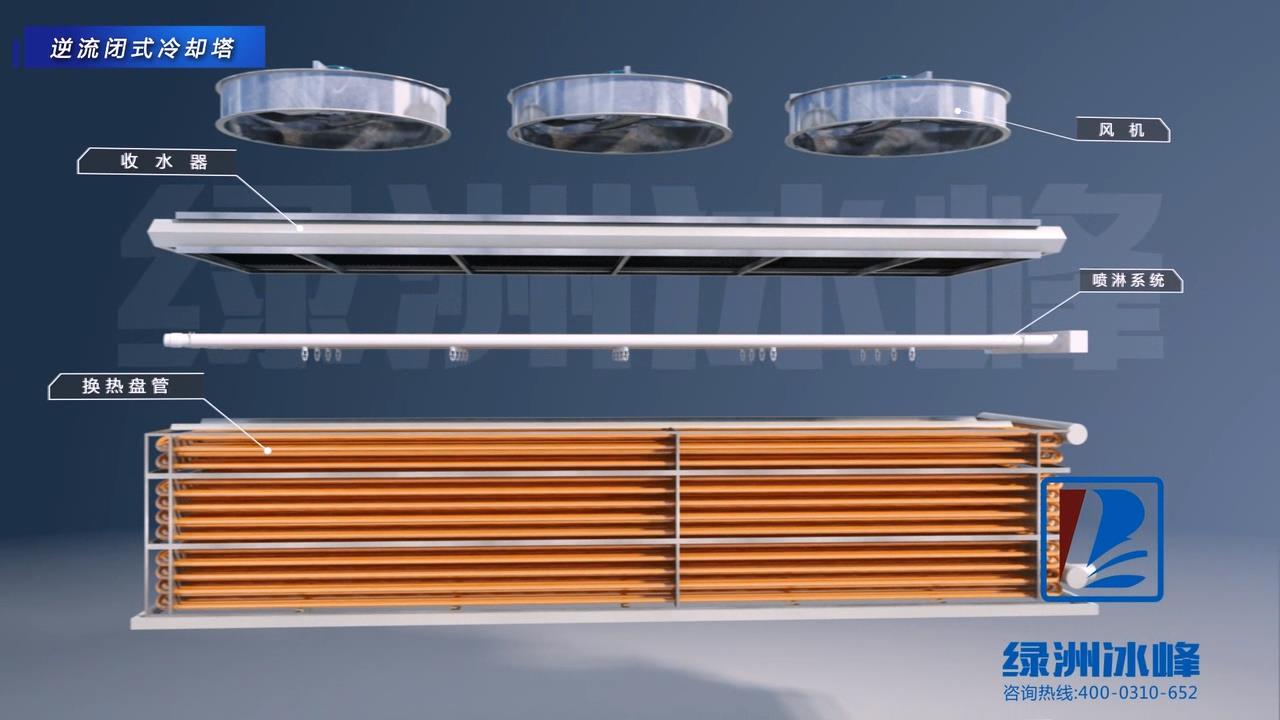

Countercurrent closed tower internal components

Three cycles

1、Internal circulation: circulating water enters the table cooler after heat exchanger and warms up through the heat source, the heat will be sent to the outside world through the table cooler, and the cooled circulating water will be sent to the heat source again by the water pump.

2, external circulation: spray water from the sink to the spray system, the water sprayed with the table cooler contact for heat transfer, part of the hot steam through the fan discharge, the cooled spray water falls to the sink after the cycle again.

3, air circulation: dry and cold air from the bottom of the countercurrent closed tower into the upward high-speed skimming coil, take away the evaporated water vapor, take away the heat energy, humidity increases, discharged by the extractor fan outside the tower.

Suitability

1, compact structure: countercurrent tower compared to the form of cross-flow, the product structure is more compact, there are more coils heat dissipation area arrangement, more suitable for cooling projects with smaller temperature difference.

2, the overall system: because the cooling tower occupies less ground, plus circulating water pump, can be made into an integrated machine, easy to move.

3, the scope of use: because the tower is compact, can be placed in the workshop, so the medium frequency power supply cooling, mechanical water jacket cooling is more suitable; for the temperature difference is small project is particularly applicable, such as water source heat pump unit group cooling.

Environmental protection and energy conservation

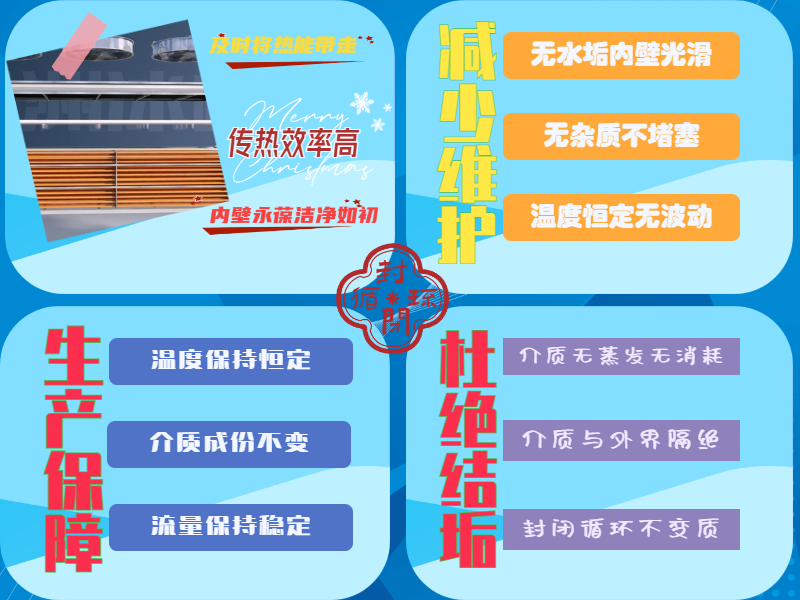

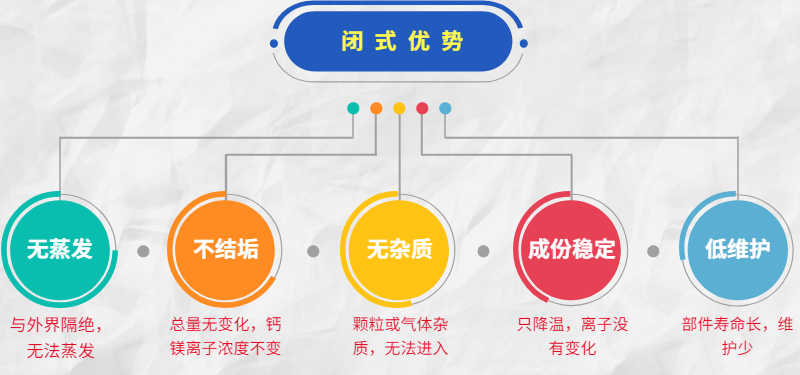

1, stable: closed cooling tower circulating water is usually soft water closed loop, effectively preventing the tower or user equipment in the long-term use of scale and damage to equipment.

2, water conservation: closed cooling tower compared with the traditional cooling tower, because of the use of a closed loop, and the use of high-efficiency dewatering devices, so it is more suitable for use in areas where water resources are scarce.

3, energy saving: closed cooling tower can be controlled according to the temperature of the number of fans to start, and the opening and closing of the spray pump, you can also install a regulator valve to control the flow.

4, environmental protection: closed cooling tower through the fully enclosed internal circuit circulating water is not polluted, can be used continuously. The relative evaporation of spray water is small, maximum protection of the environment.

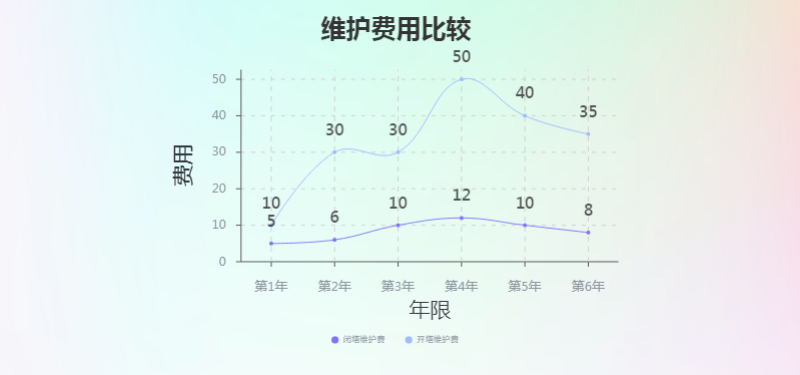

5, longer service life: our company adopts the industry's higher quality inspection level, greatly improve the corrosion resistance, the use of proper maintenance is usually more than 10 years, the later maintenance and lower costs.

Application scenario

1、Iron and steel metallurgy circulating water cooling cooling, such as blast furnace water-cooled wall circulating water, large motor circulating water, rolling bar internal circulating water;

2, the oil industry circulating water with closed cooling tower, to ensure the quality of circulating water, water and energy saving, reduce the pharmaceutical input;

3, chemical industry with closed cooling tower, compared with shell and tube heat exchanger, direct heat dissipation, reduce intermediate links, energy saving and simple;

4、Refrigeration industry, as the compressor cooling water, no pollution, no scaling, stable performance, good results;

Working process

Spray pump from the tank pumping water, pumped to the upper part of the heat exchanger coil, sprayed by the nozzle into an umbrella, continuous and uniform coverage on the outside surface of the pipe, forming a thin film of water, which part of the water to absorb high temperature refrigerant in the pipe thermal energy, converted into latent heat of vaporization, evaporation into a gaseous state, the refrigerant inside the pipe cooling cooled down or condensed into a liquid state, the non-evaporated spray water, back down to the spray water tank;

Extraction system, the top of the tower fan for the suction type, from the tower to discharge outward, the tower outside the cold dry air from the inlet grille by filtering debris into the tower, from the bottom of the heat exchanger coil upward flow, the water vapor has been evaporated away, the air humidity and temperature increase, and ultimately discharged by the fan out of the tower;

Inside the spray water tank, a float valve is set up to automatically replenish the supply when the water level is low to ensure a certain water level in the tank;

Electrical control, according to the refrigerant outlet temperature, automatic control of spray water pump and fan start and stop, to achieve energy saving.

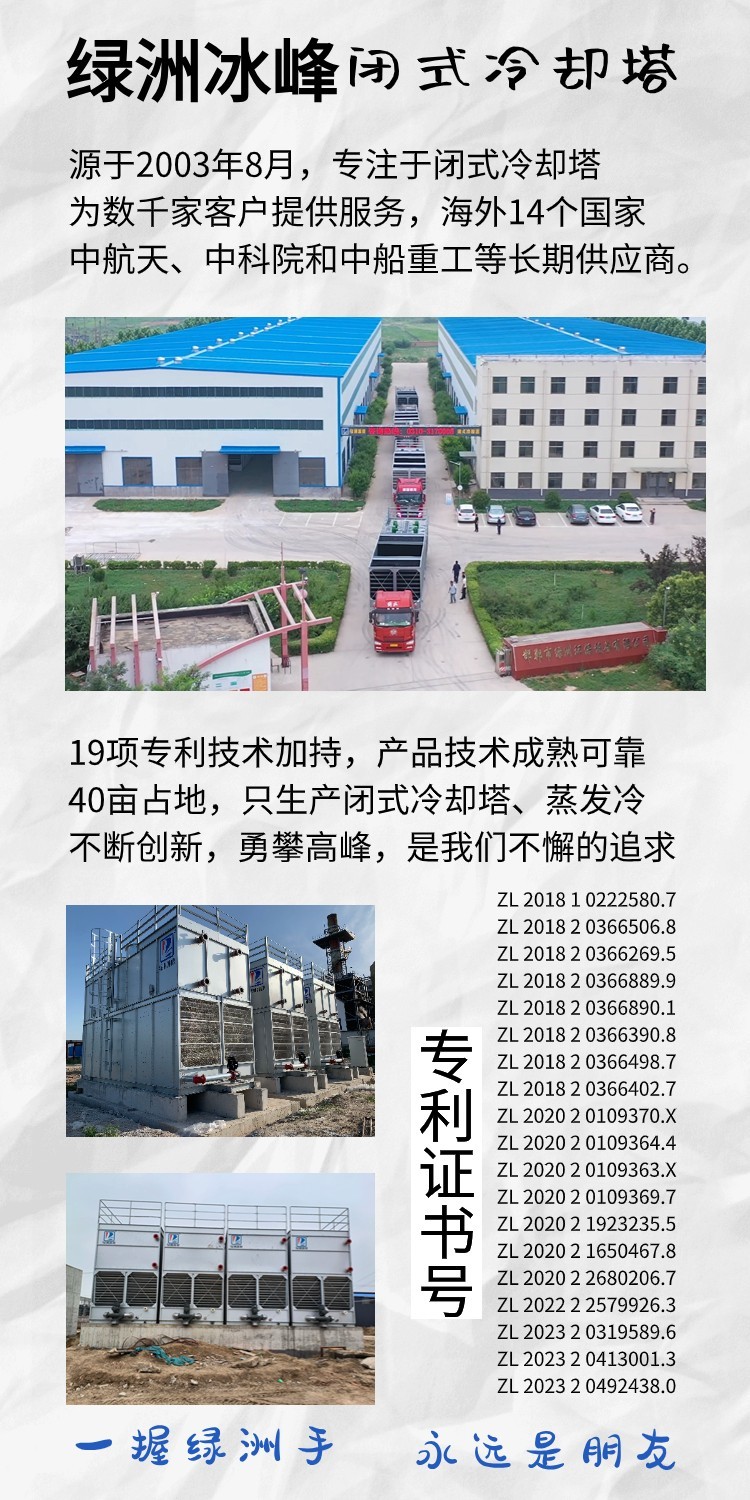

Oasis Iceberg brand advantages

Focus on 21 years, because of focus, so professional, experienced, high quality.

19 patents, patent-supported, reliable technology, excellent performance, stable operation

Covering an area of 40 acres, strong strength, strong backing, long-term cooperation, after-sales worry-free

Previous Page

Next Page