Single air inlet combined flow closed cooling tower

Compound closed-circuit cooling towers, sometimes referred to as compound closed towers, are named for the mixing of spray water and hot air. The spray water flows from top to bottom, and the air is divided into two paths: one part of the cold air flows from top to bottom, and the other part enters horizontally from the side, exchanging heat with the falling spray water through the packing to reduce the temperature of the spray water.

Key words:

Single air inlet combined flow closed cooling tower

Classification:

Hotline:

Single air inlet combined flow closed cooling tower

Overview

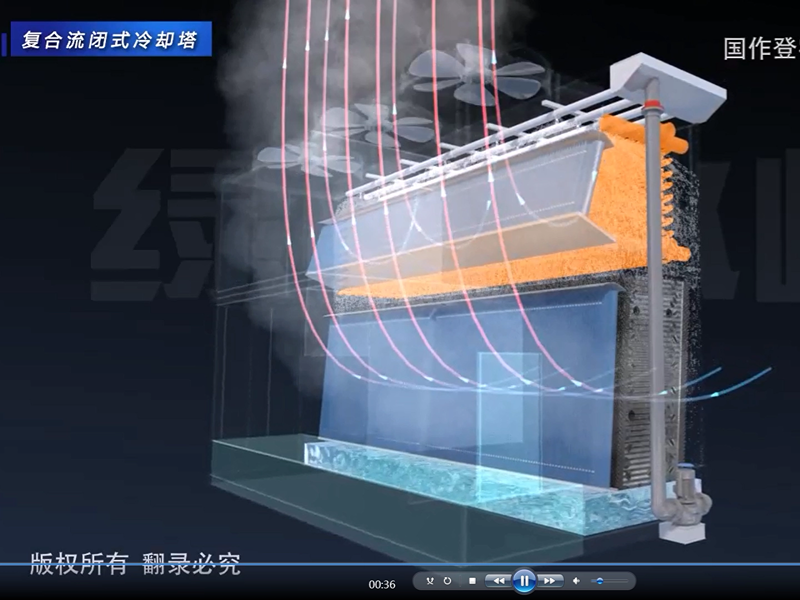

The compound counter-flow closed cooling tower, or compound closed tower for short, is a common single air inlet compound flow closed cooling tower, named for the mixing of spray water and hot air. The spray water flows from top to bottom, while the air enters in two ways: from the top and from the side. Cooling is achieved through cross-heat exchange between the packing and the spray water. The cooling tower is mainly composed of heat exchange coils, a spray system, a ventilation system, and a frame shell. Among them, the heat exchange coil is responsible for heat exchange, the spray system provides spray water, the ventilation system guides air flow, and the frame shell provides protection. This compound flow design improves cooling efficiency and is widely used in various places requiring cooling.

Working Process

► The spray pump draws water from the water tank and pumps it to the upper part of the heat exchange coil, where it is sprayed into an umbrella shape through nozzles, continuously and evenly covering the outer surface of the pipe, forming a thin water film. Part of the water absorbs the heat energy of the high-temperature refrigerant in the pipe, converting it into latent heat of vaporization and evaporating into a gaseous state. The refrigerant inside the pipe is cooled or condensed into a liquid state, and the unevaporated spray water falls back into the spray water tank.

► For the ventilation system, the fan at the top of the tower is an suction type, which draws air from inside the tower and discharges it to the outside. The cold, dry air outside the tower enters the tower through the heat exchanger coil and the air inlet grille, flowing downwards from the top of the heat exchange coil, taking away the evaporated water vapor, increasing the air humidity and temperature. At the same time, the side of the tower also draws in cold, dry air, which exchanges heat with the falling spray water through the packing. The two parts of hot and humid air are discharged out of the tower by the fan.

► A float valve is installed in the spray water tank to automatically replenish the water supply when the water level is low, ensuring a certain water level in the tank.

Working Principle

The working fluid (water, oil, or other liquid) flows in the coil, and the outer wall of the coil is wrapped by spray water. The heat of the fluid is transferred through the tube wall, forming saturated wet and hot steam with water and air. The heat is discharged into the atmosphere by the fan. The spray water reduces the temperature through the PVC heat sink during the circulation process, forming a co-current flow of cold water with the fresh incoming air. The coil mainly relies on wet and hot heat conduction. An important feature of the working principle of the compound counter-flow closed cooling tower is that it greatly inhibits the formation of scale on the outer wall of the coil.

Our Advantages

Focus on 21 years, because of focus, so professional, rich experience, excellent quality.

21 patents, patent blessing, reliable technology, excellent performance, stable operation

Covers an area of 40 acres, strong strength, strong backing, long-term cooperation, worry-free after-sales

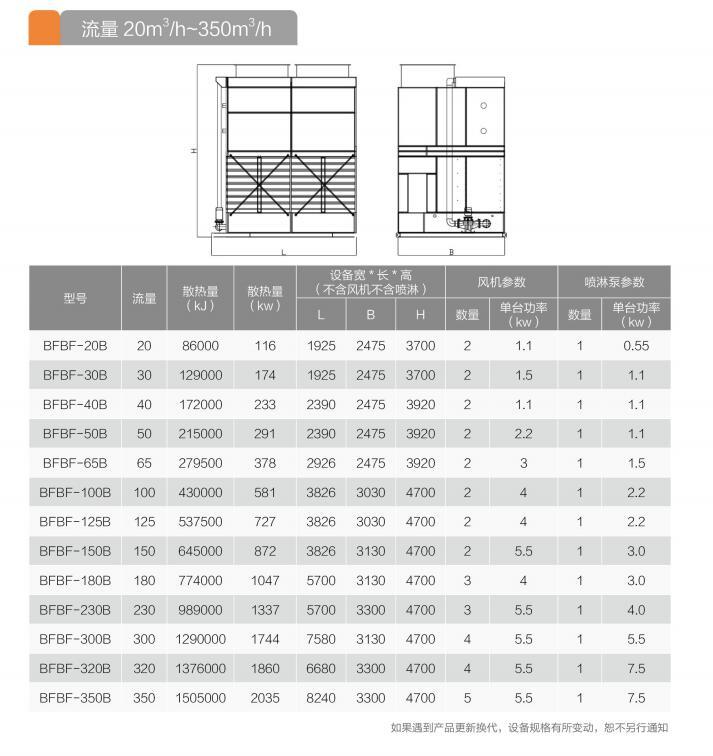

Product Model and Parameters

Add Sales Engineer Enterprise WeChat, get free technical copywriting

Previous Page

Next Page

Previous Page

Next Page

Related Products

Leave us a message