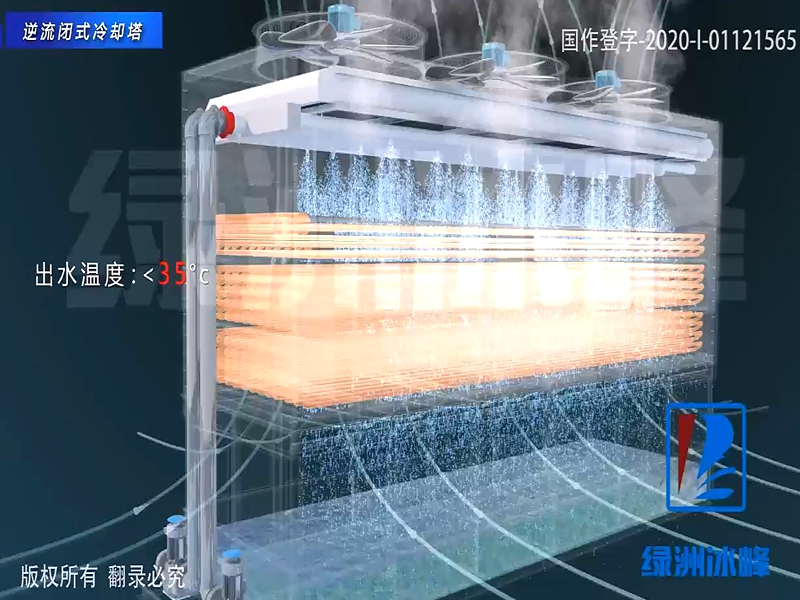

Counterflow closed cooling tower

Counterflow closed cooling tower is named for the opposite direction of refrigerant and heat medium. The spray water is sprayed from top to bottom, and the air passes through at high speed from bottom to top. It is mainly composed of heat exchange coil, spray water system, air extraction system, frame shell.

Key words:

Counterflow closed cooling tower

Classification:

Hotline:

Counterflow closed cooling tower

Overview

The counter-flow closed cooling tower is a special cooling device characterized by the opposite flow direction of the refrigerant and the heat medium. This cooling tower sprays water from top to bottom through a spray water system, while air flows at high speed from bottom to top, achieving efficient heat exchange. Its main components include heat exchange coils, spray water system, ventilation system, and frame shell. These components work together to make the cooling effect more significant. The cooling tower has a compact structure, stable operation, and is widely used in various places requiring cooling.

Working process

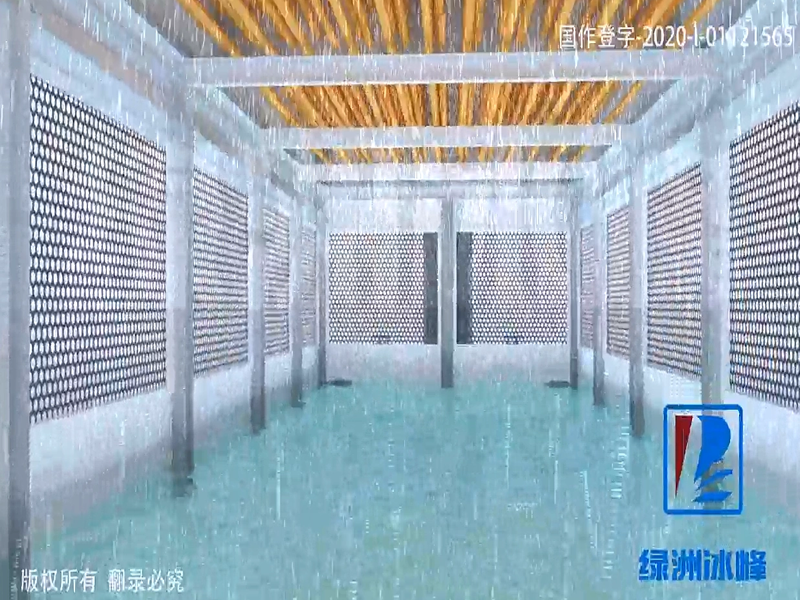

► The spray pump draws water from the water tank and pumps it to the upper part of the heat exchange coil. It is sprayed into an umbrella shape through the nozzle, continuously and evenly covering the outer surface of the pipe, forming a thin water film. Part of the water absorbs the heat of the cooled medium in the pipe, and the liquid water becomes gaseous water vapor. Evaporation carries away the heat, and the cooled medium inside the pipe is cooled or condensed into a liquid. The unevaporated spray water falls back into the spray water tank.

► Ventilation system: The fan at the top of the tower is an suction type, which exhausts air from the tower to the outside. The cold and dry air outside the tower enters the tower through the air inlet grid after filtering out debris, and flows upward from the bottom of the heat exchange coil, taking away the evaporated water vapor. The humidity and temperature of the air increase, and it is discharged out of the tower by the fan.

► A float valve is set in the spray water tank to automatically replenish the supply when the water level is low, ensuring a certain water level in the tank.

► Electrical control, online detection of the outlet temperature of the cooled medium, feedback to the data processing center, according to the temperature of the cooling medium, automatically control the start and stop of the spray water pump and fan to achieve energy saving purposes.

Operating principle of counter-flow closed cooling tower

► Internal circulation: The circulating water enters the surface cooler after being heated by the heat source equipment, and undergoes indirect wall heat exchange through the surface cooler. The cooled circulating water is then sent to the heat source equipment by the water pump.

► External circulation: The spray water is sent from the water tank to the spray system. After the water is sprayed out, it contacts the surface cooler for evaporation and heat exchange. The wet and hot steam is discharged through the fan. The unevaporated spray water falls to the water tank and is pumped to the spray system by the water pump for circulation again.

Features of counter-flow closed cooling tower

► Compact structure: Compared with the cross-flow type, the counter-flow tower has a more compact product structure, more coil heat dissipation area arrangement, and small system water resistance. It is more suitable for cooling projects with small temperature difference and large flow, such as steel metallurgy, which mostly uses this structure.

► Overall system: It can be made into dozens of units in parallel cooling, such as blast furnace water-cooled wall circulating water cooling; it can also be miniaturized, with a small footprint. After adding a circulating water pump, it can be made into an all-in-one machine for easy movement.

► Scope of use: It can be placed on the ground or on the upper part of buildings and pools, with flexible installation positions; small equipment has a compact structure and can also be placed in the workshop. Therefore, whether it is steel smelting blast furnace, continuous casting and rolling crystallizer, chemical reaction, monocrystalline silicon, heat treatment, air conditioning and refrigeration, data center, or small to high and medium frequency electric furnace power supply and induction coil cooling are used as common choices.

Our advantages

Focus on 21 years, because of focus, so professional, rich experience, excellent quality.

21 patents, patent blessing, reliable technology, excellent performance, stable operation

Covers an area of 40 acres, strong strength, strong backing, long-term cooperation, worry-free after-sales

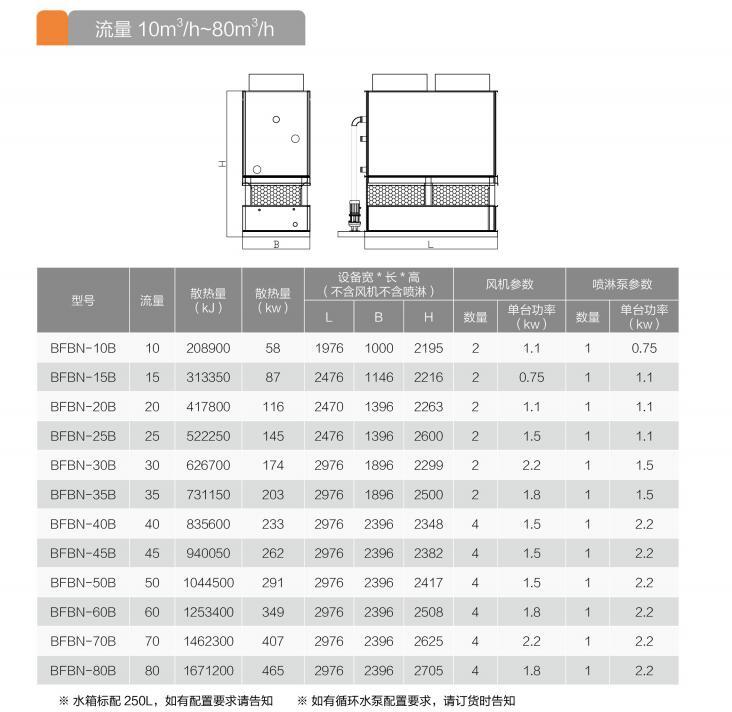

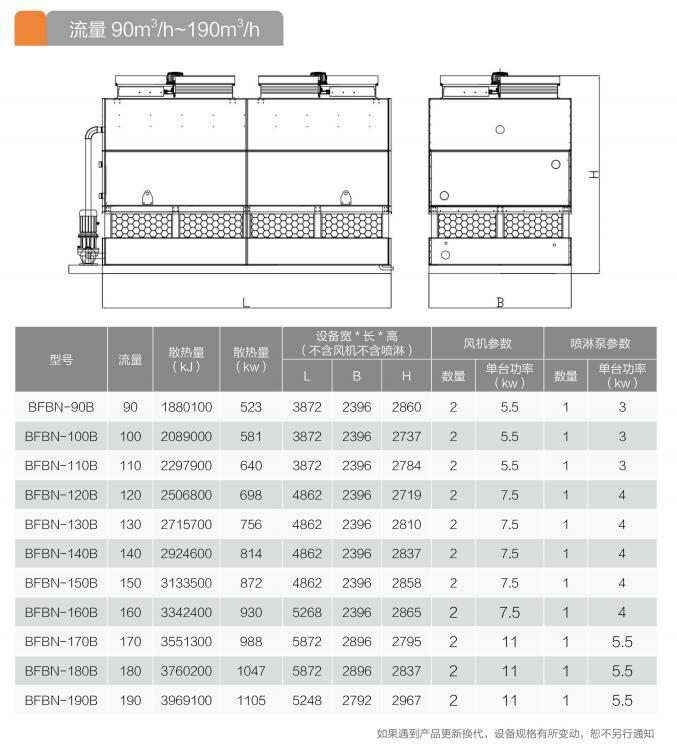

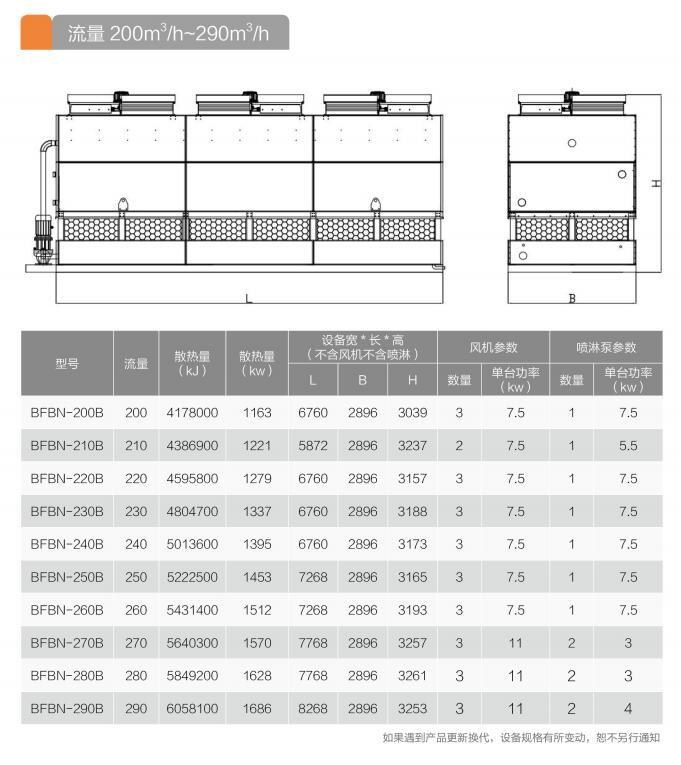

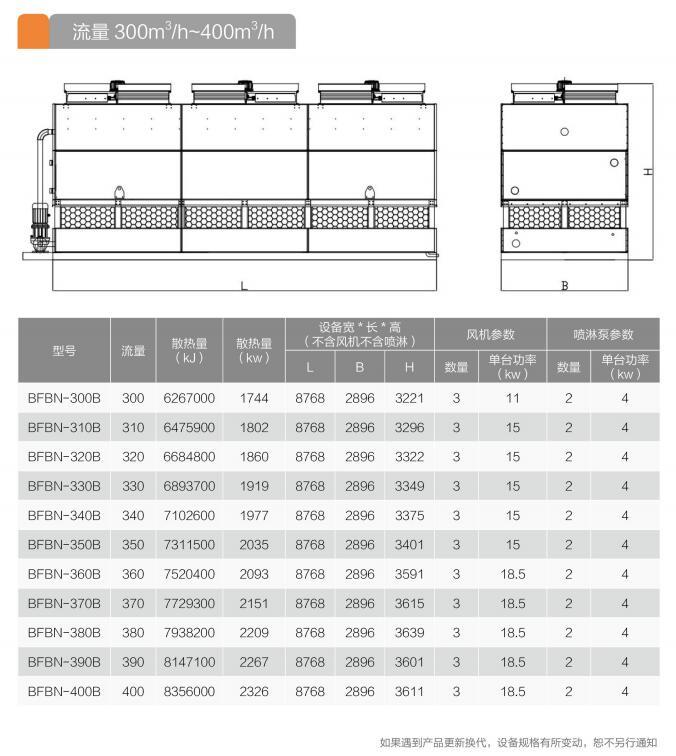

Product models and parameters

Add Sales Engineer Enterprise WeChat, get free technical copywriting

Related Products

Leave us a message