Combined Dry-and-Wet Closed Cooling Tower

The dry-wet combined closed cooling tower, often referred to simply as "dry-wet combo," "dry-wet hybrid," or "dry-wet integrated" closed cooling tower, employs a unique design that combines both dry and wet coil systems. This innovative approach leverages the advantages of each method: the dry coil takes advantage of cooler local ambient temperatures to reduce the temperature of media exceeding the dry-bulb temperature—achieving this with minimal energy consumption since it only requires kinetic energy to drive airflow—while virtually eliminating water usage. Meanwhile, the wet coil further cools the media down to nearly the wet-bulb temperature, effectively addressing the limitation of the dry coil, which cannot achieve such low temperatures. As a result, this system significantly conserves water resources, making it highly popular among users.

Key words:

Combined Dry-and-Wet Closed Cooling Tower

Classification:

Hotline:

Combined Dry-and-Wet Closed Cooling Tower

Overview

The dry-wet combined closed cooling tower, often referred to simply as "dry-wet combo," "dry-wet hybrid," or "dry-wet integrated" closed cooling tower, employs a unique design that combines both dry and wet coil systems. This innovative approach leverages the advantages of each method: the dry coil takes advantage of cooler local ambient temperatures to reduce the temperature of media exceeding the dry-bulb temperature—bringing it down close to the dry-bulb level—while consuming only the kinetic energy needed to drive airflow, resulting in zero water consumption. Meanwhile, the wet coil further cools the media to nearly the wet-bulb temperature, effectively addressing the limitation of the dry coil, which cannot achieve such low temperatures. As a result, this system significantly conserves water resources, making it highly popular among users.

Work process

► Production process equipment releases heat, which is transferred to the circulating medium—high-temperature fluid—that flows through closed pipelines and enters the combined dry-and-wet closed cooling tower.

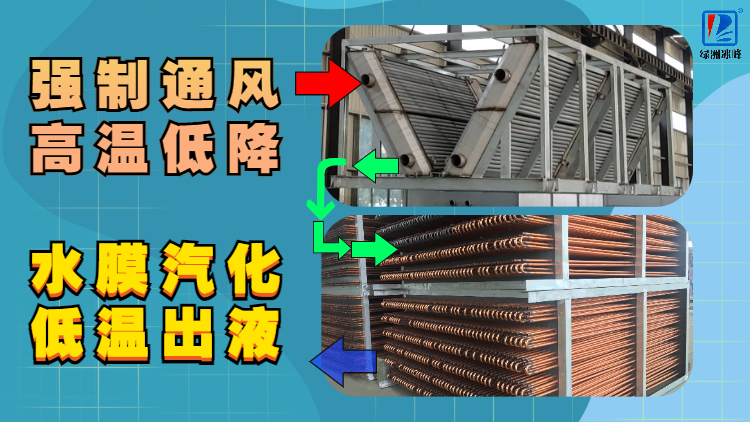

► High-temperature medium enters the dry-cooling coil, transferring heat through the base tube to the fins. As high-speed air flows past, convective heat exchange occurs, carrying away thermal energy and reducing the temperature.

► After being cooled, the medium then enters the wet-type coil, where spray water evaporates and absorbs heat through condensation, further reducing its temperature—though to a greater extent than with a dry-type coil. However, this process requires the consumption of spray water.

► The circulating medium is cooled down through dry and wet coils to meet process requirements, then returned in a closed loop back to the production equipment, where it once again transfers heat—creating a continuous, cyclical process.

Product Advantages

► Dry-type coil: Zero water consumption, no scale buildup on the outside of the tubes, and direct cooling of high-temperature media—fully leveraging the project site's naturally low ambient temperatures. By using ambient air to cool the high-temperature medium, the temperature is reduced by approximately 2–4 degrees Celsius, while maintaining a completely water-free operation.

► Wet type: High efficiency, large temperature difference, and low investment—this method reduces the circulating medium to the temperature required by the production process, thereby minimizing the investment in dry-type coils.

Application Scenarios

► Northwest Region: In water-scarce and drought-prone areas, reducing water consumption can also help lower branch operating costs.

► Areas with abundant power supply: Since dry-running systems require a large volume of air and thus demand relatively high fan motor power, they consume significant amounts of electricity. Therefore, these systems are particularly well-suited for regions where wind, hydro, tidal, and nuclear power generation are plentiful.

Case

Brand Advantages

Focused for 21 years—because of our focus, we’ve become experts, with extensive experience and unwavering quality.

21 patents, backed by patent support, ensuring reliable technology, excellent performance, and stable operation.

Covering 40 mu, with strong financial backing and a solid foundation, we offer long-term partnerships and worry-free after-sales service.

Add Sales Engineer Enterprise WeChat: Get Technical Copywriting for Free

Related Products

Leave us a message