Crossflow closed cooling tower

Crossflow closed-circuit cooling tower, named for the horizontal direction of the spray water and hot air. The spray water flows from top to bottom, and the air enters horizontally from the side, passing through the heat exchanger coils. It exchanges heat with the falling spray water, lowering the spray water temperature. It mainly consists of heat exchanger coils, a spray water system, a draft system, and a frame shell.

Key words:

Crossflow closed cooling tower

Classification:

Hotline:

Crossflow closed cooling tower

Crossflow Overview

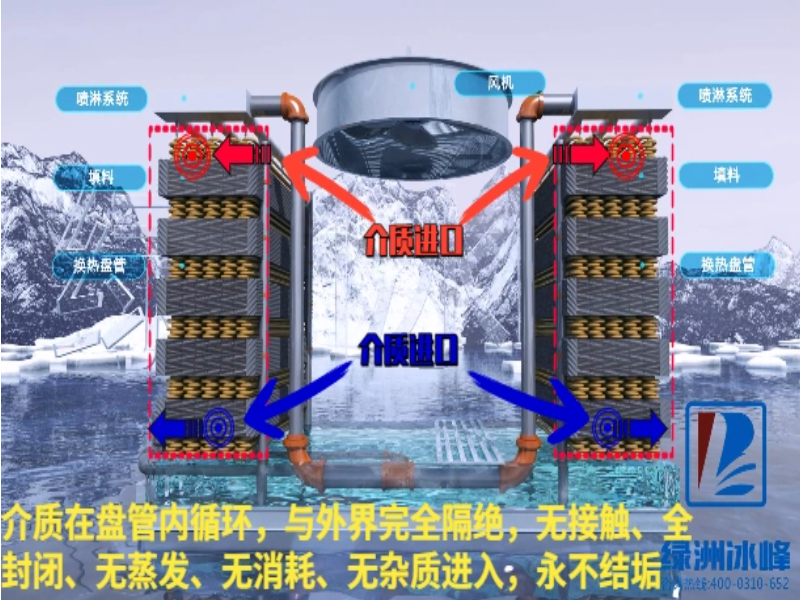

Crossflow closed-circuit cooling towers are named for the horizontal direction of the spray water and hot air. The spray water flows from top to bottom, and the air enters horizontally from the side, passing through the middle of the heat exchanger coils. It exchanges heat with the falling spray water, lowering the spray water temperature.

It mainly consists of heat exchange coils, a spray water system, a draft system, and a frame shell.

Working Process

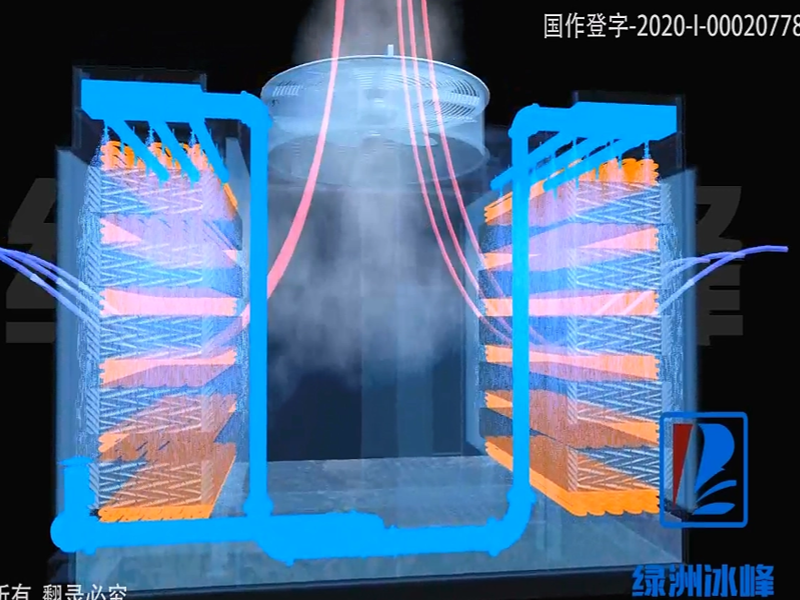

► The spray pump draws water from the sump and pumps it to the top of the heat exchange coils. It is sprayed in an umbrella shape through nozzles, continuously and evenly covering the outer surface of the pipes, forming a thin water film. Part of the water absorbs the heat energy of the high-temperature refrigerant in the pipes, converting it into latent heat of vaporization and evaporating into a gaseous state. The refrigerant inside the pipes is cooled or condensed into a liquid state. The un-evaporated spray water falls back into the spray sump;

► The draft system uses a suction-type fan at the top of the tower to draw air from inside the tower and exhaust it outwards. Cold, dry air from outside the tower enters the heat exchanger coils from the side, carrying away the evaporated water vapor. The humidity and temperature of the air increase, and the air is drawn out of the tower by a fan located between the two heat exchanger coils.

► A float valve is installed in the spray sump. When the water level is low, it automatically replenishes the supply to maintain a certain water level in the sump;

Operating Principle

► Internal circulation water system: The cooled circulating water flows out of the tower body and is sent to the heat source (equipment being cooled) by the system circulation pump. The circulating water, after being heated by heat exchange, re-enters the coils for cooling.

► External circulation water system: The external spray water cools the circulating water inside the coils by heat exchange with the coils and packing material. Then, it falls into the lower sump and is sent to the spray sump by the spray water pump for recirculation.

► The internally circulating cooled water exchanges heat and mass with the external spray water and air through the coils, avoiding direct contact between the cooled water and air, which could lead to water contamination. Because the spray water is pre-cooled by the PVC packing, the heat exchange effect is more significant.

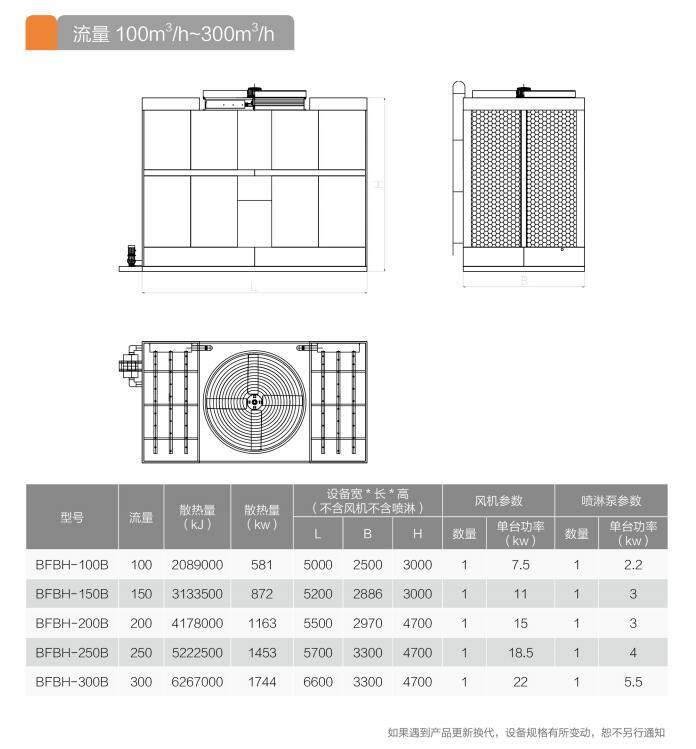

Product Models and Parameters

Add Sales Engineer Enterprise WeChat, get technical copywriting for free

Related Products

Leave us a message