13

2024

-

07

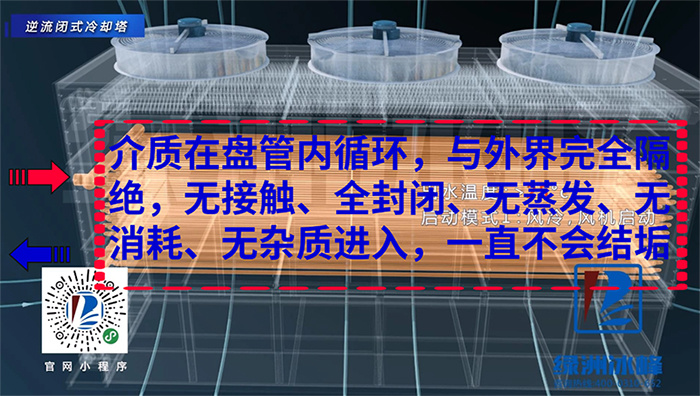

Counterflow closed cooling tower

Closed cooling tower is a kind of industrial cooling equipment, the application range is very wide. It is divided into three forms of cooling, namely, counterflow closed cooling tower, cross-flow closed cooling tower and composite flow closed cooling tower.

Closed cooling tower is a kind of industrial cooling equipment, the application range is very wide. It is divided into three forms of cooling, namely, counterflow closed cooling tower, cross-flow closed cooling tower and composite flow closed cooling tower.

Today, let's focus on understanding the lower counterflow closed cooling tower.

One: Overview

The counterflow closed cooling tower is named because the direction of refrigerant and heat medium is opposite. The spray water is sprayed from top to bottom, and the air passes by at high speed from bottom to top.

It is mainly composed of heat exchange coil, spray water system, exhaust system and frame shell.

2. working process

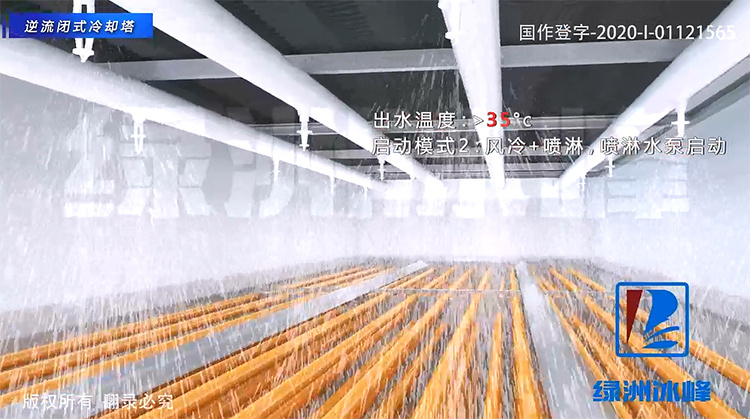

1. The spray pump pumps water from the water tank to the upper part of the heat exchange coil, sprays in an umbrella shape through the nozzle, continuously and evenly covers the outer surface of the pipe, forming a thin water film, in which part of the water absorbs the heat of the cooling medium in the pipe, the liquid water turns into gaseous water vapor, evaporates to take away the heat, the inside of the pipe is cooled or condensed into liquid by the cooling medium, and the unevaporated spray water falls back to the spray water.

2. Exhaust system: the tower top fan is suction type, which is discharged outwards by the exhaust in the tower. The cold and dry air outside the tower enters the tower through the filter debris from the air inlet grid, and flows upward from the bottom of the heat exchange coil to take away the evaporated water vapor, and the air humidity and temperature are increased, and finally discharged out of the tower by the fan;

3. In the spray tank, a floating ball valve is set. When the water level is low, it will automatically supplement the supply to ensure a certain water level of the tank;

4, electrical control, online detection of the cooling medium outlet temperature, feedback to the data processing center, according to the cooling medium temperature, automatic control of the spray pump and fan start and stop, to achieve the purpose of energy saving.

Three: working principle

1. Internal circulation: the circulating water enters the surface cooler after heat exchange and heating up through the heat source equipment, and exchanges heat between the walls through the surface cooler. The cooled circulating water is then sent to the heat source equipment by the water pump.

2. External circulation: the spray water is sent to the spray system by the water tank. After the water is sprayed, it contacts with the surface cooler for evaporation and heat exchange. The hot and humid steam is discharged through the fan. After the non-evaporated spray water falls to the water tank, it is pumped to the spray system by the water pump to circulate again.

Four: the characteristics of the counterflow closed cooling tower

1. Compact structure: Compared with the cross-flow form, the product structure is more compact and has more coil heat dissipation area arrangement, which is more suitable for cooling projects with small temperature difference and large flow.

2, the overall system: because the cooling tower occupies a small ground, plus the circulating water pump, can be made into an all-in-one machine, easy to move.

3. Scope of use: Due to the compact tower body, it can be placed in the workshop, so the cooling of the intermediate frequency power supply and the cooling of the mechanical water jacket are more suitable; it is especially suitable for projects with small temperature difference, such as the cooling of water source heat pump units.

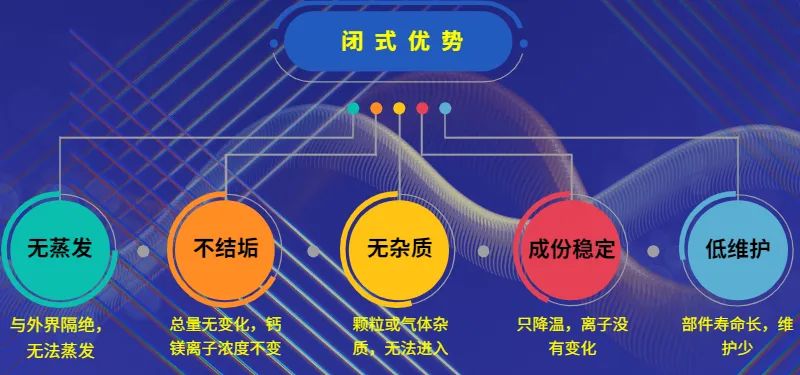

Five: the advantages of counterflow closed cooling tower

1, stability: closed cooling tower circulating water is usually soft water closed cycle, effectively prevent the long-term use of the tower or user equipment in the process of scale and damage to the equipment.

Water saving: Compared with the traditional cooling tower, the closed cooling tower is more suitable for use in areas with scarce water resources because of the use of a fully closed internal circulation and the use of high-efficiency dehydration devices.

3, energy saving: closed cooling tower can be based on the temperature to control the number of fans to start, and the spray pump to open and close, you can also install a regulating valve to control the flow.

Environmental protection: the closed cooling tower is not polluted through the fully enclosed inner circuit circulating water and can be used sustainably. Spray water relative evaporation less, to maximize the protection of the environment.

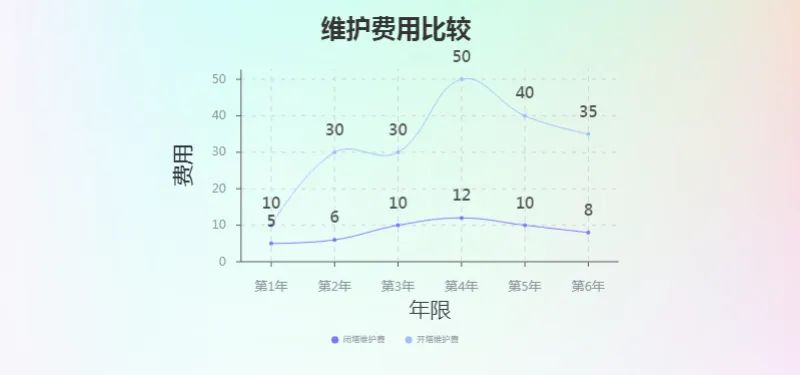

5. Longer service life: Our company adopts higher quality inspection standards in the industry, which greatly improves the corrosion resistance. The proper service life is usually more than 10, and the later maintenance and cost are lower.