19

2024

-

12

Reasons why the temperature of industrial circulating water cannot be lowered!

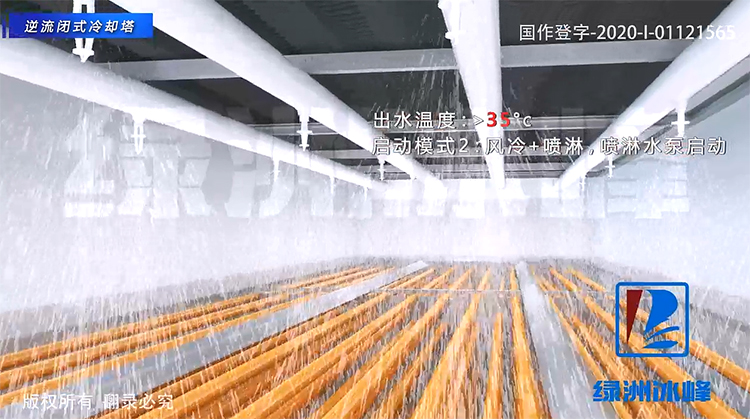

The reasons why the closed cooling tower water temperature cannot drop may involve insufficient air volume, uneven spraying, improper selection, equipment aging or damage, water quality issues, and improper operation and maintenance, among other factors. To solve this problem, it is necessary to investigate and repair from multiple angles to ensure the normal operation and cooling effect of the closed cooling tower.

The reasons why the water temperature of the closed cooling tower cannot drop may involve multiple aspects. Below is a detailed analysis of these reasons:

1. Insufficient air volumehttps://www.hdbingfeng.cn/case/7.html

Fan issues:The fan is a key component that accelerates air flow in the tower and increases the heat exchange between air and water. If the fan size is inappropriate or the installation position is improper (such as placing the cooling tower indoors or having obstructions at the air inlet), it can lead to insufficient air volume, thereby affecting the heat exchange efficiency and preventing the water temperature from dropping.

Fan failure:Deformation, breakage of fan blades, bearing damage, or failure of the drive mechanism (such as loose or broken belts) can all lead to reduced air volume, which in turn affects the heat exchange effect.

2. Uneven spraying

Clogged spray heads:Clogged spray heads can cause uneven spraying, resulting in insufficient water flow in some areas and reducing the cooling effect. Spray heads should be regularly checked, cleaned, or replaced.

Water distribution trough issues:If the water distribution trough is poorly designed or malfunctions, it can also lead to uneven spraying.

3. Improper selection

When manufacturers select models, they may not fully consider the specific operating conditions of the customer. For example, different placement positions of electric furnaces may require different models of cooling towers. Therefore, when selecting a model, it is essential to fully understand the specific cooling parameters and choose based on industry characteristics. This requires selecting experienced large manufacturers and a professional engineering team to design a suitable tower type that ensures heat dissipation while reducing investment costs.

4. Equipment aging or damage

Aging, deformation, or clogging of packing:Packing is an important component that increases the contact area between the water film and air, improving heat exchange efficiency. If the packing is aged, deformed, or clogged, it will reduce the contact area between air and water, thereby affecting the heat exchange effect.

Corrosion or damage of coils:Corrosion or damage to coils can lead to leakage of circulating water, affecting the cooling effect. At the same time, scaling or clogging of the coils can also affect heat exchange efficiency. Aging or damage of seals: Aging or damage to seals can cause water leakage at connections, thereby affecting the normal operation and cooling effect of the cooling tower.

5. Water quality issues

Deterioration of circulating water quality:Deterioration of circulating water quality can lead to scaling or clogging of coils, affecting heat exchange efficiency. Regular water quality treatment of circulating water should be conducted, such as adding descaling agents and disinfectants.

6. Improper operation and maintenance

Improper operation:If operations are not conducted according to procedures, it may lead to abnormal operation of the cooling tower, thereby affecting the cooling effect.

Insufficient maintenance:Regular maintenance and upkeep of the cooling tower are important measures to ensure its normal operation. Insufficient maintenance may lead to equipment aging, damage, or frequent failures, thereby affecting the cooling effect.

In summary, the reasons why the water temperature of the closed cooling tower cannot drop may involve insufficient air volume, uneven spraying, improper selection, equipment aging or damage, water quality issues, and improper operation and maintenance. To solve this problem, it is necessary to investigate and repair from multiple angles to ensure the normal operation and cooling effect of the closed cooling tower.

Closed cooling tower,Evaporative cooling,Closed cooling tower manufacturers,Closed cooling tower,Closed cooling tower,Wet and dry combined cooling tower