11

2025

-

06

What are the requirements for circulating water in closed cooling towers?

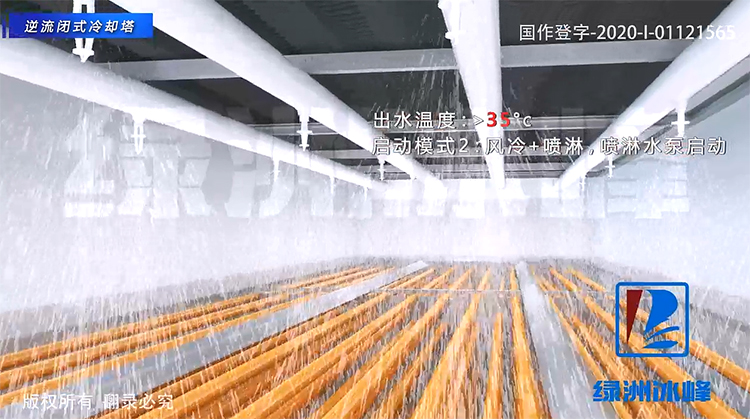

Closed-circuit cooling towers have specific requirements for both their internal circulating water (i.e., spray water/evaporated water) and the process water being cooled. These requirements directly affect the equipment's performance, efficiency, and lifespan.

Closed-circuit cooling towers have specific requirements for their internal circulating water (i.e., spray water/evaporation water) and the process circulating water being cooled These requirements directly affect the equipment's performance, efficiency, and lifespan. The following is a detailed explanation of these requirements:

I. Requirements for Internal Spray Water (Evaporation Water)

This water is sprayed onto the outer surface of the heat exchange coils within the tower, removing heat through evaporation. Although it does not directly contact the process fluid, poor water quality can still cause serious problems:

Low Suspended Solids (SS):

Requirements: Suspended solids content should be as low as possible (generally recommended < 30-50 mg/L).

Reasons: Suspended solids will deposit on the spray nozzles, packing (if any), impeller of the water pump, and the outer surface of the heat exchange coils, causing blockages, uneven water distribution, reduced heat transfer efficiency, and microbial growth. High SS is the main cause of blockages.

Low Hardness (Controlling Scaling Tendency):

Requirements: Total hardness (as CaCO₃) is recommended to be controlled at < 200 mg/L, the lower the better. The scaling tendency needs to be comprehensively evaluated in combination with alkalinity, pH, and concentration factor.

Reasons: Water evaporation leads to an increase in the concentration of calcium and magnesium ions in the water, easily forming calcium carbonate scales and other hard scales on the outer wall of the coils. Hard scale is a poor conductor of heat, significantly reducing heat transfer efficiency and increasing energy consumption.

Control Alkalinity and pH:

Requirements: The pH value is usually maintained between 7.0 - 9.0 (the specific range needs to be adjusted according to the water quality and the type of corrosion inhibitor). Total alkalinity needs to match hardness.

Reasons:

A pH that is too low (<7.0) will accelerate metal corrosion (coils, water pans, pipes).

A pH that is too high (>9.0) will promote scaling and deposition.

Appropriate pH and alkalinity help corrosion inhibitors to function and control scaling.

Control Salt Content/Total Dissolved Solids (TDS):

Requirements: TDS is recommended to be controlled at < 2000 mg/L (specific to the water source and concentration factor design). Regular blowdown is required to control the concentration factor.

Reasons: High TDS increases the risk of scaling and corrosion, affects the surface tension of the water, and may reduce evaporation efficiency. An excessively high concentration factor is the culprit behind scaling.

Control Chloride Ions (Cl⁻) and Sulfate Ions (SO₄²⁻):

Requirements: Cl⁻ < 250 mg/L (especially critical for stainless steel coils); SO₄²⁻ < 400 mg/L. The lower the concentration, the better.

Reasons: High concentrations of Cl⁻ and SO₄²⁻ are highly corrosive, especially to stainless steel (such as 304, 316) heat exchange coils, potentially leading to pitting and stress corrosion cracking. Copper pipes are also sensitive to Cl⁻.

Control Microorganisms/Algae:

Requirements: Regularly add bactericides and algicides (such as oxidizing bactericides sodium hypochlorite, chlorine dioxide; non-oxidizing bactericides such as isothiazolinones).

Reasons: Warm and humid environments are very prone to the growth of bacteria, algae, fungi, and biological slime. Slime adhering to coils reduces heat transfer, microbial metabolites corrode metals, and there are health risks such as Legionella.

Control Oils and Fats:

Requirements: Strictly prohibit oil contamination from entering the spray water system.

Reasons: Oil stains will form an oil film on the surface of the coils, seriously hindering heat transfer, and adhering to dust to form fouling.

II. Requirements for the Process Circulating Water Being Cooled

This water is in a closed loop inside the closed-circuit cooling tower's heat exchange coils Theoretically, it can be very pure (such as softened water, deionized water), and the requirements are stricter than for spray water:

Extremely Low Scaling Tendency:

Requirements: The content of scaling factors such as hardness, alkalinity, and silicon dioxide should be extremely low . Usually using softened water (hardness close to 0) or deionized water 。

Reasons: The internal channels of the coils are narrow and difficult to clean. Once scaling occurs, it will seriously affect the flow rate and heat transfer, and the cleaning cost is extremely high.

Extremely Low Corrosiveness:

Requirements: Control the concentration of dissolved oxygen, CO₂, Cl⁻, SO₄²⁻, etc. Usually, it is necessary to add corrosion inhibitors (such as molybdates, silicates, organic phosphonates, etc., selected according to the material).

Reasons: Coil materials (copper, stainless steel, carbon steel) may still corrode in a closed loop. Corrosion products will clog pipes or deposit on the pipe walls, reducing efficiency or even causing perforation and leakage.

Cleanliness:

Requirements: No particulate impurities, rust, or welding slag.

Reasons: Impurities may deposit or clog narrow flow passages inside the coils (especially at U-bends).

Chemical Compatibility:

Requirements: The process water composition must be compatible with the coil material.

Reasons: Certain special process fluids (such as high-concentration ammonia, certain organic solvents) may corrode specific metals (such as copper). The process water quality must be

clearly defined during selection.

III. Key Measures for Water Quality Maintenance

Regular Monitoring and Analysis:

For Spray Water Regular (at least monthly) testing is required: pH, conductivity/TDS, hardness, alkalinity, Cl⁻, turbidity/SS, microbial indicators.

For Process Water Regular testing is required: pH, conductivity, key ion concentration, corrosion coupons or online corrosion rate monitoring.

Chemical Water Treatment:

Spray Water System: Must add:

Scale inhibitor and dispersant: Prevent scaling of calcium carbonate, calcium sulfate, silicates, etc.

Corrosion inhibitor: Protect the tower body, water pan, pipes, and coils (outer surface) from corrosion.

Bactericide and algicide: Oxidizing and non-oxidizing sterilization methods are used alternately to control microorganisms.

Process Water System: Add a special corrosion inhibitor according to the water quality to ensure the stability of the closed system water quality.

Wastewater discharge and water replenishment control:

Automatically or manually discharge some high-concentration spray water according to the conductivity/TDS set value ( Wastewater discharge ), and replenish fresh water ( Water replenishment ), to control the concentration factor within a reasonable range (usually 3-5 times). This is the core operation to prevent scaling and corrosion.

Regular Cleaning:

Spray water side: Regularly (e.g., annually or as needed) high-pressure water flushing or chemical cleaning of the outer surface of the heat exchange coils to remove accumulated dirt and biological sludge.

Process water side: Thorough rinsing is required before system startup. If an abnormal increase in pressure drop is found during operation, professional cleaning may be required (difficult).

Closed-circuit cooling tower,Cooling tower,Closed-circuit cooling tower manufacturer,Evaporative cooling,Closed-circuit cooling tower,Closed-circuit cooling tower,Counterflow closed cooling tower,Crossflow closed cooling tower,Closed-circuit cooling tower with compound flow