11

2024

-

07

Recirculating Cooling Water System

A circulating cooling water system refers to a water supply system where cooling water transfers heat, is cooled down, and then recirculated for reuse—this system includes two types: open-loop and closed-loop.

A circulating cooling water system refers to a water supply system where cooling water transfers heat, is cooled down, and then recirculated for reuse—this system includes two types: open-loop and closed-loop.

Principle

A cooling water system that uses water as the coolant medium and recirculates it for repeated use. It primarily consists of cooling equipment, a pump, and piping systems. After cold water flows through production equipment requiring temperature reduction (commonly referred to as heat-exchanging devices, such as heat exchangers, condensers, or reactors), its temperature rises. If this heated water were simply discharged immediately—resulting in a once-through cooling system—the cold water would only be used once. However, when the warmed water is passed back through the cooling equipment, its temperature drops again, allowing it to be pumped back into the production equipment for further reuse. This significantly reduces the overall volume of water needed, often enabling savings of more than 95%. Since cooling water accounts for approximately 70% of industrial water consumption, the implementation of a cooling water recycling system plays a crucial role in conserving vast amounts of industrial water.

The cooler water from the cooling tower, which is at a lower temperature, is pressurized by a cooling pump and then sent into the chiller unit. After absorbing heat from the condenser, the water temperature rises. It’s then pumped back up to the cooling tower, where it’s sprayed downward. Thanks to the rotating cooling tower fans, the water continuously exchanges heat and moisture with the outdoor air as it falls, allowing it to cool off. Once cooled, the water collects in the cooling tower’s sump and is subsequently pressurized again by the cooling pump, ready to kick off the next cycle. This is how the process works—its principle is remarkably simple: it’s essentially a heat-exchange operation, much like the way radiators function in heating systems.

Category

Cooling equipment is divided into open and closed types, and accordingly, cooling water circulation systems are also categorized into two types: open and closed. Open systems are more complex in both design and operation.

Open-style

Cooling equipment is categorized into two types: cooling ponds and cooling towers, both of which primarily rely on water evaporation to reduce water temperature. Moreover, cooling towers often use fans to enhance evaporation, leading to significant water loss through drift. Therefore, open-loop cooling water systems must continuously replenish with fresh water. As evaporation occurs, the circulating water becomes concentrated, a process that can promote salt deposition and scaling (see "sediment control"). To counteract this concentration, make-up water is introduced, and its flow rate is typically determined based on the allowable concentration limits of the circulating water. In most cases, the amount of make-up water exceeds the losses due to evaporation and drift; hence, some portion of the circulating water must be discharged as "blowdown" to maintain a balanced water level. In open-loop systems, since the circulating water is exposed to air, contaminants such as dust and microorganisms can easily enter the system. Additionally, the escape of dissolved carbon dioxide and potential leaks of materials from heat-exchanging equipment further alter the water quality. To address these challenges, circulating cooling water often requires treatment—including sediment control, corrosion inhibition, and microbial management. The selection of appropriate treatment methods usually depends on factors like the quantity and quality of the make-up water, as well as the performance characteristics of the equipment involved. When multiple chemicals are used, it’s crucial to avoid any possible chemical reactions among them.

Closed-loop

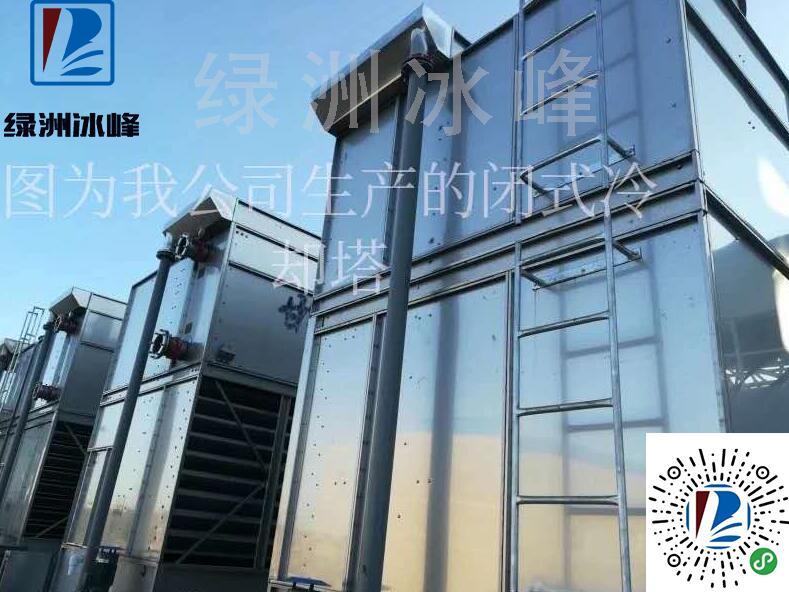

The closed-loop cooling water system utilizes closed-type cooling equipment, where circulating water flows through pipes, and heat is typically dissipated via air cooling on the pipe exterior. Apart from potential material leaks from the heat-exchange equipment, no other factors alter the quality of the circulating water. To prevent salt deposits from forming within the heat-exchange devices, the cooling water may occasionally need to be softened (see "Water Softening"). Additionally, corrosion inhibitors are often added to protect the heat-exchange equipment from corrosion. However, when using highly concentrated, acutely toxic corrosion inhibitors, safety precautions must be strictly observed. Moreover, any cooling water discharged during maintenance or repairs should be properly managed and disposed of in an environmentally responsible manner.

Advantages

1. Remove biofouling to ensure the cooling tower operates smoothly;

2. Thoroughly eliminate all types of bacteria to ensure human life and health;

3. It poses no harm to people or the environment and does not cause corrosion to equipment;

4. The system operates intelligently with stable performance, requiring no on-site personnel.

5. No need to halt production for cleaning—boosts manufacturing efficiency;

6. Reduce energy consumption in the circulation system and lower operational costs for enterprises;

7. The solution is fully biodegradable and can be discharged directly, eliminating additional costs for subsequent wastewater treatment.

Industrial Applications

Cooling the heat-generating parts of semiconductor manufacturing equipment:

Single-wafer cleaning and transfer systems, printing machines, automatic chuck mounting devices, spray coating systems, ion-plating equipment, etching units, single-wafer processing systems, dicing machines, packaging machines, temperature management for developer solutions, exposure units, and heating devices for magnetization sections, among others.

Cooling the heating section of the laser device:

Laser processing, the heating components of welding machines, laser marking devices, generating units, and carbon dioxide laser processing machines, among others.

Cooling the heating components of machinery used in other industries:

Plasma welding, automatic packaging machines, mold cooling systems, cleaning machinery, gold-plating tanks, precision grinding machines, injection molding machines, and the molding sections of resin molding machines, among others.

Analyzing the cooling of the machine's发热 (heating) components:

The light source for the electron microscope, the light-emitting portion of the ICP optical emission spectrometer, the heating element in the spectrophotometer, the heat source of the X-ray analyzer, the heated section of the automatic pulse generator, and the light source for the atomic absorption spectrophotometer, among others.

Cooling of coolant for CNC machine tools and machining centers.

Scan the official QR code above to discover more interesting facts and helpful tips!

You can learn more details about pre-sales, after-sales service, and repairs—as well as make purchases—through our official WeChat account. We look forward to your visit!

Address: No. 1 Xingfu Road, Feixiang Economic and Technological Development Zone, Handan City, Hebei Province

Sales hotline: 0310-3178005 400-0310-652

We sincerely welcome your call!

Handan Oasis Environmental Equipment Co., Ltd. looks forward to collaborating with you!