11

2024

-

07

The difference between closed-circuit cooling towers and open-circuit cooling towers

An open-circuit cooling tower is a device that uses the contact between water and air to dissipate waste heat generated in industrial processes or in refrigeration and air-conditioning systems through evaporation. The basic principle is as follows: Dry (low-enthalpy) air is drawn into the cooling tower via a fan, entering from the air intake section. Simultaneously, high-temperature water molecules—rich in saturated vapor pressure—move toward the lower-pressure air. Meanwhile, warm, moist water is sprayed into the tower by the water distribution system. When water droplets come into contact with the air, heat is transferred directly through the interface between water and air. At the same time, due to the pressure difference between the water vapor surface and the surrounding air, evaporation occurs under the influence of this pressure gradient. This process removes the sensible heat from the water as it transfers heat to unsaturated dry air, while some of the water evaporates, carrying away its latent heat. Ultimately, this mechanism effectively cools the circulating water.

Open-circuit cooling tower:

An open-circuit cooling tower is a device that uses the contact between water and air to dissipate waste heat generated in industrial processes or in refrigeration and air-conditioning systems through evaporation. The basic principle is as follows: Dry (low-enthalpy) air is drawn into the cooling tower via a fan, entering from the air intake section. Simultaneously, high-temperature water molecules—rich in saturated vapor pressure—move toward the lower-pressure air. Meanwhile, warm, moist water is sprayed into the tower by the water distribution system. When water droplets come into contact with the air, heat is transferred directly through the interface. At the same time, due to the pressure difference between the water vapor surface and the surrounding air, evaporation occurs under pressure. This process removes the sensible heat from the water as it exchanges heat with unsaturated dry air, while partial evaporation also carries away the latent heat stored in the water. Ultimately, this mechanism effectively cools the circulating water.

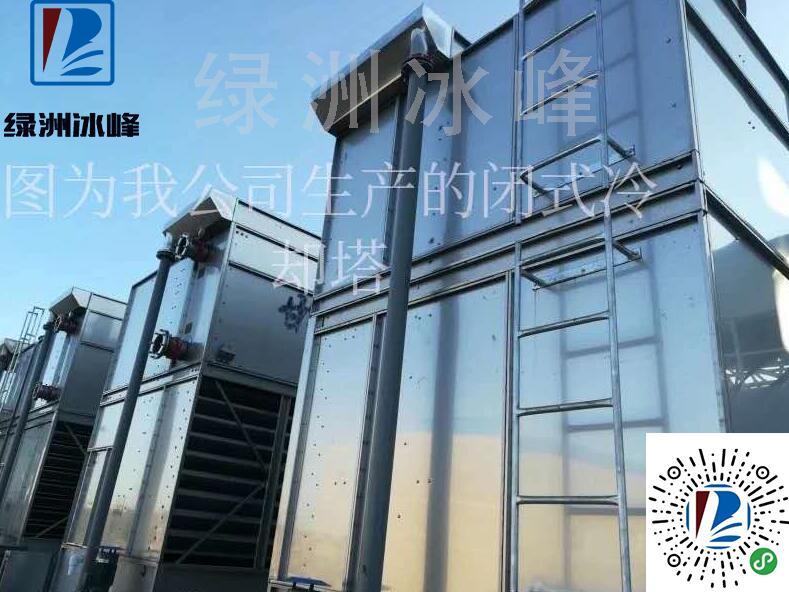

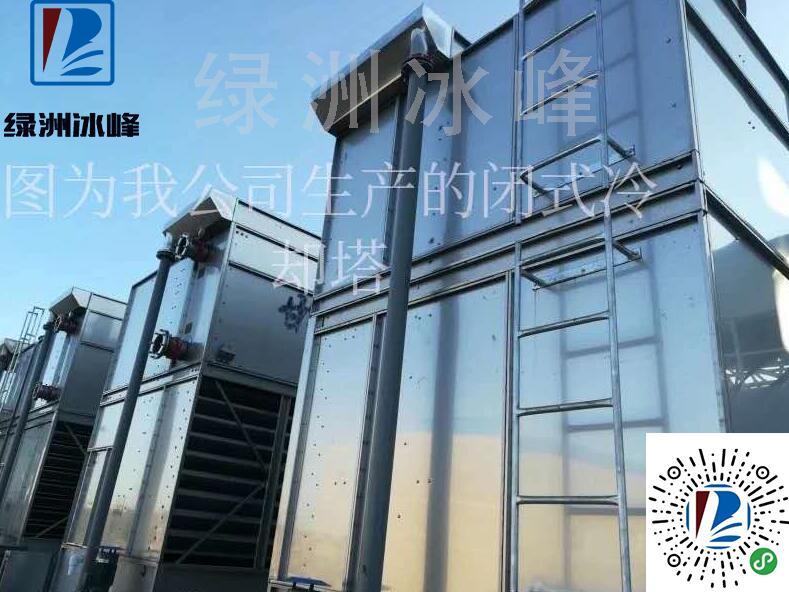

Closed-circuit cooling tower

It works by bringing water into contact with coils, where heat is transferred through the tube walls to remove the heat from the cooling medium inside the coils, thus achieving the cooling effect. In a closed-loop cooling tower, the circulating water only moves within the tower itself, exchanging heat with air to cool down before coming into contact with the coils and absorbing the heat from the working fluid inside. A make-up water line replenishes any water lost due to evaporation or drift. Compared to open-loop cooling towers, the most distinctive feature of closed-loop systems is the addition of coils: the liquid coolant—designed for specific cooling needs—is routed through steel coils without direct contact with the water, relying instead on heat exchange conducted via the tube walls.

Here are the key differences between open- and closed-type cooling towers:

01. The cooling principles differ. As described in the concept above, in a closed-loop cooling tower, the coolant circulates entirely within the cooling coil without direct contact with air, whereas in an open-loop cooling tower, the coolant passes directly through the packing for cooling.

02. The cooling methods differ. Closed-circuit cooling towers utilize a dual-loop cooling system—combining air cooling and water cooling—while open-circuit cooling towers operate on a single-loop system, relying solely on air cooling.

03. Different cooling media are used. Closed-loop cooling towers can directly cool water, oils, alcohols, quenching fluids, brines, and chemical solutions—media that experience no loss and maintain stable compositions—whereas open-loop cooling towers can, in principle, only cool water.

04. Cooling temperatures differ. Closed-loop cooling towers can handle high-temperature media, while open-loop cooling towers can, in principle, only cool water below 65°C—this largely depends on the material of the heat dissipation fins.

05. Prices vary; closed-loop cooling towers are relatively more expensive, typically costing three to five times as much as open-loop cooling towers.

06. Energy-saving performance differs. Closed-circuit cooling towers have significantly lower drift rates and evaporation losses compared to open-circuit cooling towers.

07. The level of protection provided to the cooled equipment differs significantly. In a closed-loop fluid system, the fluid circulates in a sealed manner, preventing contamination, evaporation, and concentration—eliminating the need for regular water top-ups or chemical additions. This ensures both the operational reliability and extended lifespan of connected equipment, while also simplifying daily maintenance. In contrast, open cooling towers rely on an open-loop fluid system where evaporation leads to fluid concentration, necessitating continuous chemical treatment and water replenishment throughout the year. Moreover, since the fluid is directly exposed to air, it’s prone to contamination. Under sulfurous weather conditions, the fluid can even undergo acidic reactions, potentially damaging the connected equipment.

08. Maintenance requirements differ. Closed-loop cooling towers do not require frequent shutdowns for maintenance, ensuring stable and safe operation while helping to reduce the failure rate of associated equipment—making them ideal for systems that need continuous operation. In contrast, open-loop cooling towers must be regularly shut down for maintenance, which makes them unsuitable for systems requiring uninterrupted operation.

09. Performance differences in usage: For instance, the circulating fluid in a closed cooling tower remains free from algae and salt crystallization because it’s shielded from sunlight and doesn’t come into contact with air—eliminating the need for algae or salt removal—and thus ensures high system performance. In contrast, the circulating fluid in an open cooling tower operates openly, exposed to sunlight, making it prone to algae growth and salt crystallization, which can negatively impact the system’s operational efficiency.

10. Environmental friendliness: Closed-circuit cooling towers can operate in dry mode without fostering the growth of various pathogens, making them particularly suitable for applications requiring air purification—and they are also frequently used in water-scarce, arid regions. Open-circuit cooling towers, however, cannot operate in dry mode.

11. Safety: When the fluid is volatile, toxic, or corrosive, closed-circuit cooling towers utilize a sealed circulation system that prevents environmental contamination, making them widely suitable for systems with stringent fluid requirements. In contrast, open-type cooling towers pose safety risks when handling volatile, toxic, or irritating solutions due to their open design.

Summary:

Open-loop cooling towers and closed-loop cooling towers have significant differences, but there’s no such thing as a "better" or "worse" cooling tower—only one that best suits the needs of the cooling system. Different cooling systems require different cooling methods and tower designs. When selecting a cooling tower, customers can make informed comparisons based on their specific process requirements and budget. At Oasis Ice Peak, we leverage specialized equipment and conduct precise calculations tailored to the local environmental conditions, including temperature and humidity, to deliver superior cooling performance for our clients.

1. Stability: Closed-loop cooling towers typically use softened water for recirculation, effectively preventing scale buildup inside the tower or in user equipment over extended periods—and thereby protecting equipment from potential damage.

2. Water Conservation: Compared to traditional cooling towers, closed-loop cooling towers are better suited for use in regions with scarce water resources, thanks to their fully enclosed internal circulation system and the incorporation of highly efficient dehydrating devices.

3. Energy Efficiency: Closed-circuit cooling towers can control the number of fans started based on temperature, as well as manage the operation of spray pumps. Additionally, regulating valves can be installed to precisely control the flow rate.

4. Environmental Protection: The closed-loop cooling tower prevents water contamination through its fully enclosed internal circulation system, ensuring sustainable use. Additionally, the spray water exhibits minimal evaporation, maximizing environmental protection.

5. Longer Service Life: Our company employs industry-leading quality control standards, significantly enhancing corrosion resistance. As a result, these products typically last more than 10 years with proper use and maintenance, while subsequent upkeep and associated costs remain low.

The Oasis Ice Peak BFL series closed-circuit cooling towers feature advanced cooling technology, along with optimized equipment structure and materials, making the products more efficient, energy-saving, environmentally friendly, and delivering superior overall stability—and excellent value for money!

Scan the official QR code above to discover more interesting facts and helpful tips!

Pre-sales, after-sales, and maintenance—everything from purchasing to service details can be explored through our official WeChat account. We look forward to your visit!

Address: No. 1 Xingfu Road, Feixiang Economic and Technological Development Zone, Handan City, Hebei Province

Sales hotline: 0310-3178005 400-0310-652

We sincerely welcome your call!

Handan Oasis Environmental Equipment Co., Ltd. looks forward to collaborating with you!

Previous Page

Previous Page