13

2025

-

08

Application scenarios of evaporative condensers!

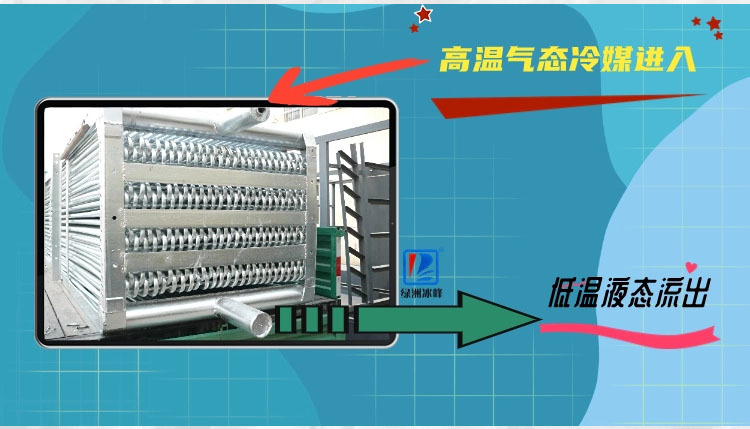

An evaporative condenser is an efficient device that uses water evaporation to absorb heat and condense refrigerant. It combines the high efficiency of water cooling with the water-saving advantages of air cooling and is mainly used in the following scenarios:

An evaporative condenser is a type of that uses water evaporation to absorb heat to achieve efficient refrigerant condensation, combining the high efficiency of water cooling and the water-saving advantage of air cooling , mainly applied in the following scenarios:

1. Core Application Areas

1. Industrial refrigeration systems

Cold storage and cold chain logistics :

Condensation of ammonia (NH₃) or freon (R717/R404A) systems in large cold storage warehouses (below -25°C) and refrigerated distribution centers.

Food processing :

Refrigeration units for meat freezing, dairy cooling, and beer fermentation tanks.

Chemical production :

Cooling of reaction kettles, gas liquefaction (such as LNG precooling), and refrigeration processes in petrochemical workflows.

2. Heating, Ventilation, and Air Conditioning (HVAC)

Large central air conditioning :

Chillers in commercial complexes, hospitals, and airports (especially suitable for centrifugal/screw compressors).

District cooling stations :

Condensation heat dissipation in centralized energy stations, replacing traditional cooling tower + shell-and-tube condenser combinations.

3. Energy and power

Auxiliary equipment cooling in power plants :

Gas turbine inlet cooling and auxiliary refrigeration systems in nuclear power plants.

Ground source heat pump supplementation :

Used as peak load heat dissipation supplement when soil thermal balance is insufficient.

4. Special process cooling

Plastic molding :

Hydraulic oil cooling for injection molding machines and condensation end of mold temperature control systems.

Pharmaceutical industry :

Refrigeration units for low-temperature reaction kettles and freeze dryers.

Data centers :

Direct cooling or indirect liquid cooling system heat dissipation for high-temperature server rooms.

2. Common Requirements for Applicable Scenarios

High-efficiency heat dissipation requirements

Need to maintain stable condensation pressure in high-temperature environments (>35°C) or high humidity areas (evaporative condensers are 30~50% more efficient than air-cooled ones).

Water-saving needs

In water-scarce areas or regions with high water prices (water consumption is only 10~25% of that of water-cooled condensers).

Space constraints

Installation sites are limited (compact design saves space, no cooling water pool needed).

Pollution prevention requirements

Avoid cooling water contacting refrigerant (closed-loop design prevents impurities from entering the system).

Closed-circuit cooling tower,Closed Circuit Cooling Tower Manufacturer,Evaporative Condenser,Cooling Tower,Closed Cooling Tower,Closed-circuit cooling tower,Combined Wet and Dry Cooling Tower,Industrial Cooling Tower,Closed-circuit cooling tower,Closed Circuit Cooling Tower