Evaporative condenser

Evaporative condenser, is commonly known as a name, also known as closed cooling tower. In fact, it is also known as closed cooling tower, the use of evaporation of spray water, brought out of the tower by the air, for cooling the circulating medium in the heat transfer tubes, the circulating medium is completely isolated from the outside world. Because the circulating medium being cooled is isolated from the outside world, completely closed, sometimes called evaporative condenser. Internal circulating medium, only cooling, no consumption without evaporation. As the heat exchanger tube outside the spray water vaporization, a large amount of water vapor and air mixing, humidity increases, by the axial fan, these saturated, high humidity, high enthalpy air out of the tower in the environment.

Key words:

Evaporative condenser

Classification:

Hotline:

Evaporative condenser

Summarize

Evaporative condenser, is commonly known as a name, also known as closed cooling tower.

In fact, it is also known as closed cooling tower, the use of evaporation of spray water, brought out of the tower by the air, for cooling the circulating medium in the heat transfer tubes, the circulating medium is completely isolated from the outside world.

Because the circulating medium being cooled is isolated from the outside world, completely closed, sometimes called evaporative condenser. Internal circulating medium, only cooling, no consumption without evaporation.

As the heat exchanger tube outside the spray water vaporization, a large amount of water vapor and air mixing, humidity increases, by the axial fan, these saturated, high humidity, high enthalpy air out of the tower in the environment.

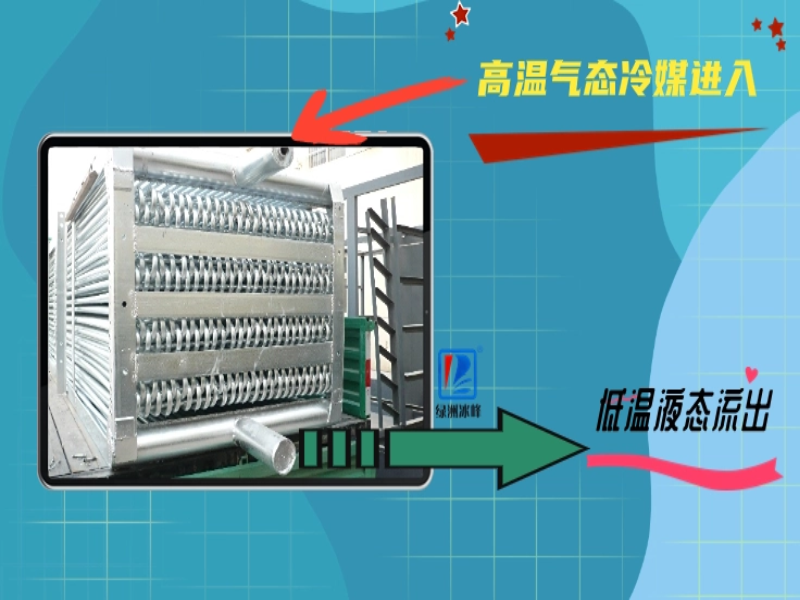

Working process

► Latent heat of vaporization: basically the same as the closed cooling tower, relying on the evaporation of the spray water outside the heat exchanger tube, absorbing the latent heat of vaporization, and taking away the heat energy of the industrial circulating water medium in the closed heat exchanger tube;

► Between the wall heat transfer: spray water and air, and the circulating medium is completely isolated, without any contact, only heat transfer, no contact.

Key Benefits

► No evaporation: only cooling, no evaporation, no consumption, the circulating medium is completely isolated from the outside air, without any contact, no medium evaporation consumption and impurities into the internal media to ensure the stability of the composition.

► No scaling: due to no evaporation, the media scale ions such as calcium, magnesium, sulfate and other concentrations have not changed, so there will be no scaling.

► No algae production, good environmental performance;

► Water and electricity saving, winter and spring and fall seasons, when the temperature is low, there may be no need to spray water, as long as the air-cooling can meet the cooling requirements, the water saving effect is obvious; automatic operation, no need for manual intervention, when the temperature reaches the set requirements, the automatic stopping of the spray pump or fan.

Application scenario

Mostly used in iron and steel metallurgy, casting and smelting, petrochemical, chemical, light textile, machinery and electric power and other heavy industries, not easy to scale, reduce evaporation, commonly used in demineralized water, pure water, etc. cooling, cooling in the closed heat exchanger tubes, and the outside atmosphere is completely isolated.

► Iron and steel metallurgy: blast furnace, continuous casting and rolling, crystallizer, air compressor and so on;

► Large casting: melting furnace, inverter, quenching liquid, etc;

► Petroleum smelting: reaction kettle, smelting furnace, heat exchanger, etc;

► Chemical Light Textile: reaction kettle, etc;

► Air conditioning and refrigeration: compressor, etc;

Previous Page

Next Page

Previous Page

Next Page

Related Products

Leave us a message